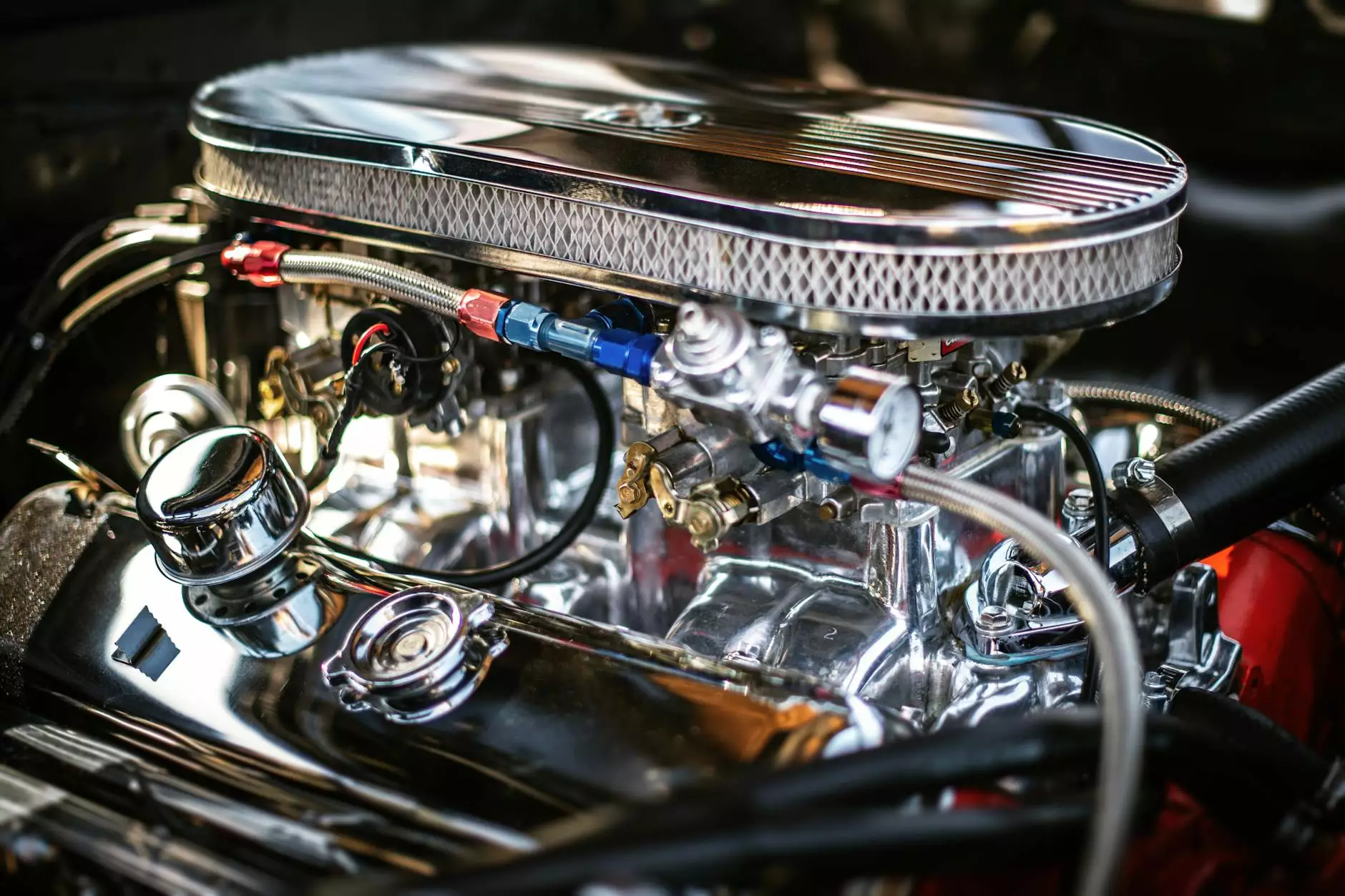

The Best Cylinder Liner Manufacturers for Automotive and Auto Customization

Introduction

Welcome to client-diesel.com, your one-stop destination for all your automotive and auto customization needs. We take pride in being one of the leading cylinder liner manufacturers in the industry, providing top-quality products that guarantee exceptional performance and longevity for your vehicles.

Why Choose Our Cylinder Liners?

When it comes to cylinder liners, quality and precision are of utmost importance. Our team of highly skilled engineers and technicians works tirelessly to ensure that our products meet and exceed industry standards. Here's why you should choose our cylinder liners:

1. Exceptional Durability

Our cylinder liners are manufactured using the finest materials available, ensuring exceptional durability and resistance to wear and tear. Whether you're running a high-performance racing vehicle or a heavy-duty work truck, our cylinder liners are built to withstand even the most demanding conditions.

2. Precise Engineering

We understand the critical role that cylinder liners play in engine performance. That's why we employ cutting-edge engineering techniques and technologies to manufacture cylinder liners that meet the strictest tolerances. Our precision engineering ensures optimal fit, enhanced sealing, and improved combustion efficiency.

3. Extensive Range

At client-diesel.com, we offer an extensive range of cylinder liners suitable for various automotive applications and customization needs. Whether you require cylinder liners for passenger cars, commercial vehicles, or heavy machinery, we have the perfect solution to meet your requirements.

4. Customization Options

We understand that every vehicle and engine is unique. That's why we offer customization options for our cylinder liners, allowing you to tailor the product to your specific requirements. From material selection to dimensional variations, we can work with you to create a cylinder liner that perfectly suits your needs.

The Manufacturing Process

Our cylinder liners undergo a meticulous manufacturing process to ensure the highest quality and precision. Here's an overview of our manufacturing process:

1. Material Selection

We only source materials from reputable suppliers known for their quality and reliability. Our engineers carefully select the appropriate material based on the intended application, ensuring optimal performance and durability.

2. Machining and Honing

Using state-of-the-art CNC machines, our skilled technicians accurately machine the cylinder liners to achieve the desired dimensions and specifications. We then utilize honing processes to create a smooth and even finish, promoting excellent piston ring lubrication and efficient heat transfer.

3. Quality Control

Quality control is at the core of our manufacturing process. We conduct rigorous inspections at every stage to ensure that our cylinder liners meet the highest standards. From material composition checks to dimensional accuracy tests, we leave no room for compromise.

4. Surface Treatment

Surface treatment plays a vital role in enhancing the durability and longevity of cylinder liners. We offer various surface treatment options, including advanced coatings and heat treatments, to provide superior wear resistance and minimize friction.

Conclusion

When it comes to finding reliable and high-quality cylinder liner manufacturers for your automotive and auto customization needs, look no further than client-diesel.com. With our exceptional durability, precise engineering, extensive range, and customization options, we are confident that our cylinder liners will exceed your expectations. Choose us for top-notch products that will enhance the performance and longevity of your vehicles. Contact us today to discuss your requirements or explore our website for more information.